Cubic feet per minute is crucial for optimal plant growth, as it regulate airflow and ventilation to prevent decay in plants and keep them healthy and green. However, if you don’t understand the CFM concept, you can choose either a smaller or a bigger fan and harm plants.

The actual CFM that a growing space needs differs from the CFM that the fan manufacturer advertises. The advertised CFM often refers to the FAD or TP rating, which measures the fan’s output under ideal conditions with no restrictions on airflow.

In real-world applications, however, several factors reduce the actual CFM. These include losses due to friction in the ductwork, static pressure in the air line, and additional equipment like carbon filters that add resistance to the airflow.

To calculate the CFM properly, determine the factors that influence the actual CFM, such as the room size and the air changes per hour.

Table of Contents

What does CFM stand for?

CFM stands for Cubic Feet per Minute, which measures the volume of air a fan moves in one minute. It’s a crucial specification when considering inline fans, as it indicates their capacity to move air.

Regarding inline fans, CFM is important because it indicates how much air the fan can circulate in a given space. The higher the CFM, the more powerful the fan and the larger the volume of air it can move. The CFM is relevant for environments like grow tents, where proper ventilation is critical to maintaining optimal growing conditions.

If an inline fan provides low CFM, it does not ensure adequate ventilation, leading to issues such as poor air quality, excess humidity, and encouraging mold growth. Conversely, high CFM results in over-ventilation, which leads to excessive drying or temperature fluctuations.

CFH, or Cubic Feet per Hour, is another measure of air volume movement, but it’s calculated over an hour instead of a minute. To convert CFH to CFM, you simply divide the CFH value by 60 (since there are 60 minutes in an hour).

While CFH can measure an inline fan’s airflow, it’s not commonly used in the context of grow tents. This principle applies primarily because the rapid air exchange required in these environments makes the per-minute measurement (CFM) more relevant and practical.

What is a good CFM for a fan?

The CFM for a fan suitable for a grow tent can vary depending on the size of the tent, the type of plants you are growing, and other factors like heat generated by lights and equipment.

For instance, a good CFM for a ceiling fan in a 12×12 room is around 3,000 CFM, typically achieved with a 44″ ceiling fan. Meanwhile, small rooms need a fan with a CFM between 1,000 to 2,000. If your tent has a volume of up to 402 cubic feet, a 6-inch fan is suggested.

Remember, your intake fan should be about 20-30% less powerful than your main exhaust fan.

In the case of computer case fans, an example provided specifies a 120mm fan running at 1200 rpm with a CFM of 28.34, which is considered adequate.

Regarding household fans, their range is between 100 CFM for small personal fans and higher for larger ones, with the given measurements: good – 4,000 to 5,000 CFM, better – 5,000 to 6,000 CFM, best – over 6,000 CFM.

Why must you care about CFM tests when buying an inline fan?

You need to care about CFM tests as they ensure reliable products, but you cannot always trust the values since they are determined under ideal conditions that don’t not reflect real-world use.

Sellers promote the CFM rating to customers in two main methods: Free air delivery – FAD and Total Pressure – TP.

The FAD refers to a measure of the volume of air that a fan can move when there is no resistance, resulting in a higher CFM rating in a controlled environment with no obstructions or ductwork attached to the fan. The fan can move as much air as possible, and the CFM rating will be at its maximum.

However, there is always some resistance in real-world applications, whether from ductwork or filters. So while FAD can make a fan’s CFM rating appear higher, it may not accurately reflect their performance under actual operating conditions.

TP is another method used to measure a fan’s performance. It measures the total pressure created by a fan, which includes both velocity pressure (caused by the movement of air) and static pressure (caused by resistance to airflow).

A high TP rating can result in a higher CFM rating because it indicates that the fan can overcome significant resistance and still move a large volume of air. However, like FAD, a high TP rating may not accurately reflect a fan’s performance with actual ductwork or filters in a real-world setting.

There is a CFM test to ensure the fan provides enough CFM for your needs. It measures the volume of air that an air-moving device, like a fan or air conditioning system, can move in one minute. The measurement is taken when the fan is at its maximum speed and without any restrictions on the airflow.

The CFM test is crucial because it provides a standardized measurement of a fan’s performance. It allows consumers to compare different models and brands effectively and choose the one that best suits their needs.

What types of CFM test certificates are there?

CMF certificates ensure your products are reliable and offer precise readings, and reputable organizations conduct them. You should always choose products with CFM test certificates from reputable organizations.

These organizations conduct rigorous testing under standardized conditions to ensure accurate and reliable performance data, including Home Ventilating Institute (HVI), American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), Air Movement and Control Association (AMCA).

HVI (Home Ventilating Institute) is a prominent organization that provides a Certified Ratings Program for ventilation products ensuring that products meet certain performance standards, including accurate CFM ratings. HVI-certified products undergo rigorous testing and are continually monitored to ensure they maintain the standards set by the institute.

ASHRAE is a global society advancing human well-being through sustainable technology for the built environment. They develop standards and guidelines for many aspects of heating, ventilation, air conditioning, and refrigeration (HVACR), including the measurement of fan performance. ASHRAE Standard 51/AMCA Standard 210 is widely accepted for measuring the airflow rate of fans.

AMCA is a global association that creates standards for the fan industry, including measuring fan performance. Like ASHRAE, AMCA uses Standard 210 for measuring airflow rates. Fans that bear the AMCA seal have been independently tested and certified for performance following this standard.

You can find a certification 0.2” w.g. static pressure issued by such organizations. Static pressure, measured in inches of water gauge (w.g.), is the pressure that an inline fan must overcome to move air through a system. It’s caused by resistance from things like ductwork, filters, and grilles. The higher the static pressure, the harder a fan has to work to move air.

When a fan is “certified at 0.2” w.g. static pressure,” it means that its performance metrics were measured under conditions where the fan had to overcome a static pressure of 0.2 inches of water gauge.

This certification can be very useful when choosing a fan for a specific application, as it gives you a better idea of how much CFM a fan will provide under real-world conditions rather than just free air delivery (FAD) conditions.

Why should you buy inline fans with CFM certified with HVI?

You should buy inline fans with CFM certified with HVI as such fans provide reliable performance ratings, comparable and credible product information, assurance of quality air flow, and energy efficiency.

When you buy an HVI-certified fan, you can trust that its performance ratings, including CFM, are accurate and not inflated. This means that the fan will perform as advertised under real-world conditions. This assurance is crucial because inflated performance ratings are common for non-HVI-certified fans.

HVI’s Certified Ratings Program provides a voluntary means for ventilation manufacturers to report comparable and credible product information. This makes it easier for consumers to compare different products and make informed decisions.

Certified fans offer extra assurance that you get the best air flow quality from the product you purchase. The CFM rating of a fan determines its airflow capacity, which is crucial for maintaining good air quality.

HVI-certified fans often meet high standards of energy efficiency. For example, fans can be Energy Star certified, which means they use less energy than standard models without compromising performance.

How to calculate CFM fan?

To calculate how much CFM you need in a fan:

- Determine the size of your growing space.

- Determine how many times per hour you want the air to change.

- Adjust the results based on static pressure in ducts and ventilation systems.

First, measure and calculate the volume of the space in cubic feet by multiplying the room’s length, width, and height.

Next, specify the Air Changes per Hour (ACH). ACH is the number of times you want to replace the air in the space in an hour completely. The ACH needed will depend on factors such as the type of plant and its growth stage. For instance, a mature cannabis plant in the flowering stage requires an ACH of around 60, while a young plant in the vegetative stage only needs an ACH of 30.

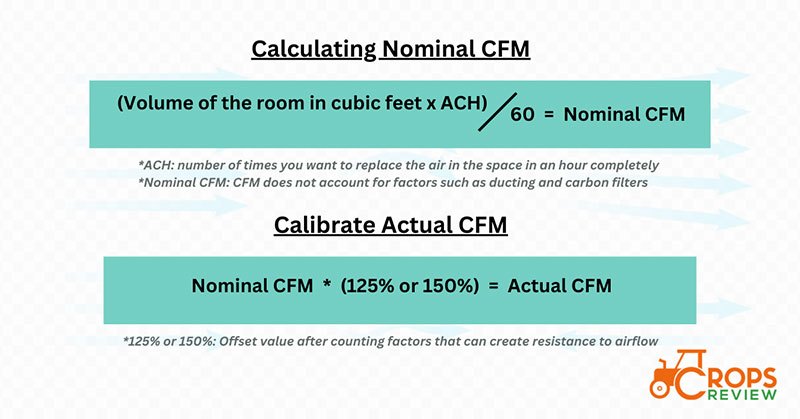

Then, calculate the required CFM. The basic formula for calculating CFM is:

CFM = (Volume of the room in cubic feet x ACH) / 60

For example, if you have a 300 cubic foot room and want an ACH of 30, you would need a fan with a CFM rating of (300 x 30) / 60 = 150 CFM.

However, this calculation does not account for factors that can create resistance to airflow, such as ducting and carbon filters. These factors increase the static pressure that the fan must overcome, which reduces its actual CFM in practice.

Experts recommend increasing the calculated CFM by 25% to 50% to compensate for these factors. So if your calculations indicate you need a fan with a CFM of 150, you might actually want to choose a fan with a CFM of around 200 to 225 to ensure adequate ventilation.

Assume you have a grow room or grow tent with dimensions of 4 feet in width and 8 feet in length. To determine the area in square feet, you’d multiply these two measurements together, giving you 32 square feet. If we consider the height to be 8 feet, then multiplying this by the area gives you a total volume of 256 cubic feet.

To figure out the required Cubic Feet per Minute, multiply the total cubic footage of your space by the number of times you want the air to be changed in an hour. In this scenario, 256 cubic feet multiplied by eight desired air changes every hour gives you a total of 2,058 cubic feet per hour. As an hour consists of 60 minutes, you would then divide 2,058 by 60, resulting in a requirement of 34 CFM.

Now, let’s understand the cubic feet per minute ratings in relation to the fan size. For instance, a 1000 CFM fan can move 1000 cubic feet of air per minute. It is suitable for a 1000 cubic foot room with an ACH of 60 (i.e., complete air change every minute).

A 600 CFM fan is suitable for a 600 cubic feet room with an ACH of 60, or a larger room with a lower ACH.

A 2000 CFM fan can handle a 2000 cubic feet room with an ACH of 60 or a larger room with a lower ACH.

Larger fans like 5000 CFM or 15000 CFM fans are typically used in commercial or industrial settings where more air needs to be moved.

What is the relationship between CFM and static pressure in a flow line?

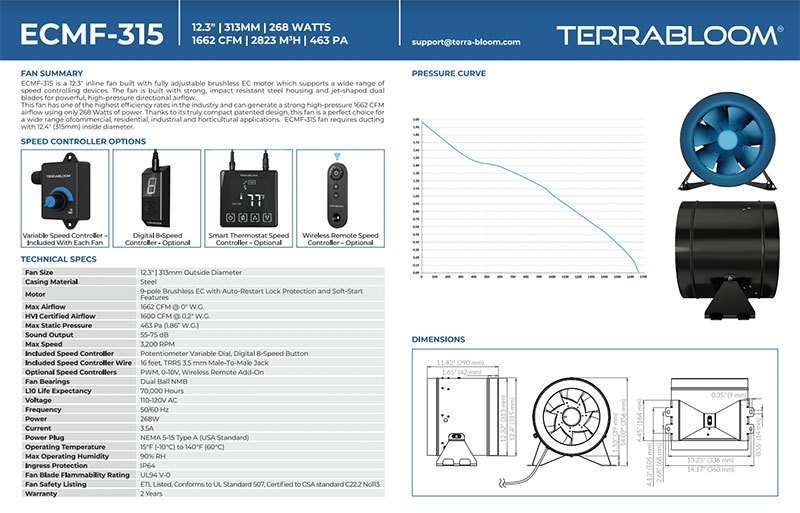

A pressure curve is a graphical representation that shows the relationship between the pressure within a system (like an air duct) and the airflow rate, measured in Cubic Feet per Minute, that a fan can produce at different pressure levels. The pressure curve is created through testing with an inline fan CFM test, which measures the fan’s output at varying pressure levels.

Static pressure refers to the resistance to airflow in a heating, ventilation, and air conditioning (HVAC) system. The higher the static pressure in the air line, the harder the fan moves air and the lower the actual CFM received. The fan must overcome this resistance or “pressure” to push air through the system. Look at the picture for a better understanding.

Source: TerraBloom

For instance, a carbon filter might introduce an equivalent of 0.5-0.8″ w.g. (inches of water gauge) pressure. It causes the fan to lose 30-50% of its output when it has to blow or pull air through that filter. Therefore, if a fan originally produced 1000 CFM at 0″ w.g., it might only produce 500-700 CFM when a carbon filter introducing 0.5-0.8″ w.g. of pressure is added. The best inline duct fan jumps in to help the fan obtain a higher CFM for optimal operations.

Manufacturers often provide pressure curves so customers can understand the expected performance of a fan in their specific setup, including the impact of added components like carbon filters.

What are the factors that affect fan CFM?

The three factors affecting a fan CFM are RPM, blade size, and pitch.

RPM (Revolutions Per Minute) refers to the speed at which the fan blades rotate. The higher the RPM, the more air low the fan can move, resulting in a high CFM. However, this also depends on other factors, like the size and pitch of the blades.

The size of the fan blades also significantly impacts the CFM. Larger blades can move more air flow than smaller ones, so fans with larger blades typically have high CFM levels.

The pitch of a fan blade is the angle at which it cuts into the air flow. Blades with a steeper pitch move more air because they cut into and push more air with each revolution. Therefore, fans with a higher blade pitch typically have more CFM.