Adding ballast to a tractor tire helps improve its stability and traction on various surface types.

It makes tackling difficult terrain much easier, improving the tractor overall. In this comprehensive guide, we will go over the basics of how to put ballast in your tractor tires so that you can get the most out of your agricultural machinery.

We’ll talk about what kinds of materials can be used as tractor ballast, how changing the weight affects handling and traction, how to put ballast in place and make sure it stays there, and how to keep the soil compacted when you’re driving over rough spots on your property.

Read on if you want to know all about improving the movement capability and efficacy of your heavy-duty vehicles!

Take away key points:

- Tractor ballasting is a process used to increase the weight of a tractor by filling its tires with liquid ballast, which enables efficient traction and inflation pressure.

- When filling the tire, use the same type of liquid as originally filled in order to maintain proper inflation pressure and safety.

- Monitor the temperature range recommended by the manufacturer and make sure not to exceed this range while filling.

- Regularly check for leaks and replace any damaged valve stem before beginning the ballasting process in tractor wheels and tires.

Table of Contents

- Understanding the importance of tractor ballast

- Deciding which ballast material to use for your tractor tires

- Measuring and calculating the proper amount of ballast for your tractor

- Testing and adjusting your tractor tires for optimal performance after ballasting

- Maintaining and monitoring the ballast in your tractor tires over time

- Liquid ballasting 101: Covering the basics

- FAQs

- Conclusion

Understanding the importance of tractor ballast

If you own and operate a tractor, understanding the importance of ballast in your tractor tires is crucial.

The term “ballast” refers to the weight added to a tractor to improve traction and stability. Without proper ballast to the rear tires, front axle, and rear axle, a tractor can become unstable or even tip over, causing serious injury or damage.

By adding tractor ballast to your tractor tires, you can increase the weight and balance of your machine. This will help you move and control your tractor better, especially when working on difficult terrain or when the weather is bad.

Proper ballasting can also save money on gas, make tires last longer, and keep the soil from getting too hard. Make sure to evenly distribute the weight from the front axle and rear axle.

It’s important to note that not all tractors will require the same amount or type of ballast. Factors such as tractor weight, tire size, and the type of work being done will all impact your ballasting needs.

Deciding which ballast material to use for your tractor tires

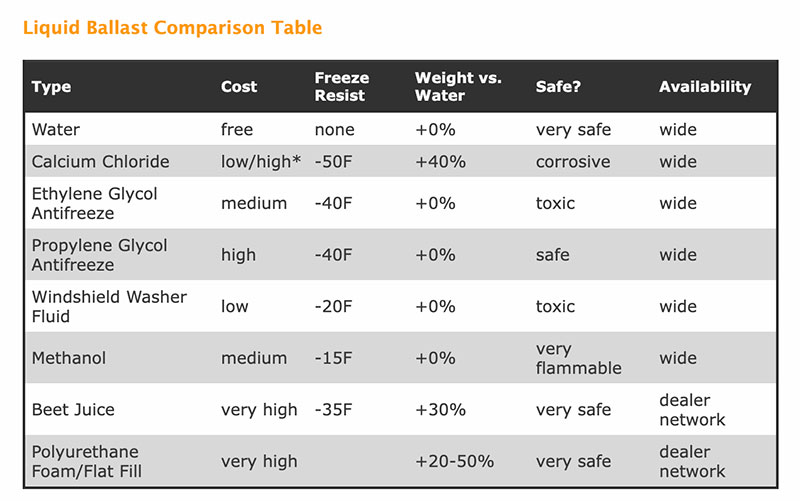

Here are some common ballast materials and their characteristics:

Water: Water is a common ballast material for tractor tires as it’s readily available and can be easily added or removed from the tires. However, water can freeze in colder temperatures and potentially cause tire damage.

Calcium chloride: Calcium chloride is a popular ballast material as it’s denser than water and can provide more weight per volume. It’s also less likely to freeze than water and doesn’t cause tire damage.

Beet juice: Beet juice has become a popular alternative to traditional ballast materials due to its eco-friendliness and ability to reduce tire wear and tear. It’s also non-toxic and doesn’t cause harm to soil or crops.

Polyurethane foam: Polyurethane foam is a permanent ballast solution that’s injected into tires as a liquid and then hardens to fill tires. It’s ideal for tractors that require increased weight and stability for heavy-duty tasks.

Measuring and calculating the proper amount of ballast for your tractor

Measuring and calculating the proper amount of ballast for your tractor is essential to ensure optimal performance and safety.

Here are some steps to follow when determining the right amount of ballast for your tractor:

Determine the weight of your tractor: The weight of your tractor is a crucial factor in calculating the required amount of ballast. Consult your tractor’s manual or manufacturer to find out the exact weight of your machine.

Calculate the maximum torque: The maximum torque is the amount of force that your tractor can generate and is another important factor when determining ballast requirements. You can find this information in your tractor’s manual.

Identify the heaviest load: The heavy load that you intend to carry with your tractor will also impact the amount of ballast required. Make note of the weight of the heaviest load you’ll be carrying. This will prevent premature wear of the tire thread.

Calculate the weight of the ballast: Depending on the type of ballast material you choose, the weight can vary. Calculate the weight of the ballast material you’ll be using per unit of volume. When a vehicle is carrying too much weight, it not only uses more fuel but also results in inadequate slip, which can lead to the destruction of soil structure and potential stress on transmission components.

Decide on the desired weight distribution: Determine the desired weight distribution based on the type of work you’ll be doing with your tractor. Different types of work may require different weight distributions.

Calculate the ballast weight: Use the information collected from steps 1-5 to calculate the ideal amount of ballast needed for your tractor. Make sure this amount is evenly distributed across the tractor tires for optimal balance and stability.

Testing and adjusting your tractor tires for optimal performance after ballasting

After adding ballast to your tractor’s tires, you should test and adjust them to make sure they work as well as possible. Here are some steps to follow:

Check tire pressure: Check the tire inflation pressure of each tire to ensure it’s within the recommended range. Adjust the inflation pressure as needed.

Check tire tread: Make sure the tread depth of each tire meets the minimum standards. Replace any tires with worn or damaged treads.

Test tractor operation: Take your tractor for a spin and test its operation with the added ballast. Pay attention to how it handles turns, hills, and other obstacles. If the tractor feels unstable or unbalanced, adjust the ballast accordingly.

Check wheel slip: Wheel slip occurs when the tractor’s wheels spin without moving the tractor forward. Check for wheel slip on various surfaces and slopes. If wheel slip is excessive, adjust the ballast to improve traction.

Adjust ballast as needed: Based on the performance of your tractor, adjust the ballast as needed to achieve optimal weight distribution and balance.

Re-test tractor operation: After making any adjustments to the ballast, take your tractor for another spin to test its performance. Repeat the testing and adjusting process until the tractor handles optimally and is balanced.

Maintaining and monitoring the ballast in your tractor tires over time

Maintaining and keeping an eye on the ballast in your tractor’s tires is important to make sure they work well and keep you safe. Here are some steps to follow:

Check ballast regularly: Regularly check the ballast in your tractor tires to ensure it hasn’t shifted or leaked. Make sure it’s still distributed evenly across the tires.

Monitor tire pressure: Keep an eye on tire pressure, especially if you notice changes in how your tractor is handling or if there are fluctuations in temperature. Adjust the pressure as needed to maintain optimal performance.

Check for cracks and leaks: If you’re using a liquid ballast material, such as calcium chloride or beet juice, regularly check the tires for cracks, leaks or other damage. Damaged tires should be replaced immediately.

Adjust ballast for changing conditions: Different work conditions, such as weather or terrain, call for different weight distributions. Adjust the ballast as needed to maintain optimal balance and stability.

Liquid ballasting 101: Covering the basics

Liquid ballasting is a process of adding weight to tractor tires by filling them with liquid. This is done to make the tractor work better and be more stable on different terrains.

Here’s what you need to know about liquid ballasting.

Benefits of liquid ballasting for tractor tires

Filling tractor tires with liquid, a practice known as “liquid ballasting,” adds weight split to the tires.

It significantly improves the traction and stability of the tractor while reducing soil compaction, the risk of tire damage, and fuel consumption. Additionally, when the added weight is pressing the tires into the soil, this ensures more engine horsepower to be used and transmitted into power.

It is more cost-effective than other ballasting methods and is considered an efficient solution for enhancing tractor performance and stability on rough terrain. For the liquid ballasting process to work, the tires must be properly prepared, filled, and taken care of.

Types of liquid ballasts for tractor tires

Common liquids used for ballasting include water, antifreeze, and oil-based fluids.

Water: Water is one of the most common liquid ballasts due to its low cost and easy availability. It is non-toxic and provides a good amount of weight for better traction and stability. However, it freezes at temperatures below 32 degrees Fahrenheit, which may cause the tire to burst if not properly heated or sealed in cold weather conditions.

Antifreeze: Automotive antifreeze (ethylene glycol) is commonly used as liquid ballasts due to their higher weight-to-volume ratio than water. They also have a much higher boiling point and freezing point (depending on the type), making antifreeze a suitable option in extreme temperatures. The downside of using antifreeze is that it can be corrosive when exposed to certain materials, such as rubber or aluminum components of the tractor.

Windshield washer fluid: Easy to find and cheap per gallon; windshield washer fluid is a popular ballast because it is cheap and easy to use. When used at full strength in tires, it offers freeze protection until temperatures of -20F and has the same weight as water.

The liquid ballasting process: Step by step

The liquid ballasting process with tractor tires typically follows these steps with the right tools:

Preparation: Proper preparation of the tire is essential for success. Make sure the tire is properly inflated and in good condition before proceeding. Clean any dirt or debris from the inside and outside of the tire to ensure that it is free of any obstructions.

Filling: Determine the type and amount of the proper ballast required, depending on the weight you want to achieve. Fill tractor tires with a hose or pipe until it reaches the desired level and make sure that no air bubbles are present within the tire.

Sealing: Use a valve core stem core tool to seal off the opening of each tire, preventing any liquid from escaping or entering into it unintentionally. Seal each tire with a tight-fitting cap that will prevent any air or moisture from entering or leaving it during use.

Maintenance: Monitor your tractor tires regularly for signs of wear and tear, as well as proper inflation levels; this will help extend their life by ensuring they are not overfilled with liquid ballasts, which can cause pressure buildup in them over time if left unchecked. Replace inner tubes and caps as needed to keep them in good condition for long-term performance benefits.

FAQs

How much liquid ballast in tractor tires?

The amount of liquid ballast required for tractor tires depends on the weight and size of the tire, as well as the level of traction needed for specific tasks.

Generally speaking, a standard front tire should contain between 30 to 40 quarts (approximately 750 to 1000 liters) of liquid ballast in order to provide adequate traction and stability.

Rear tires may need up to 60 quarts (1500 liters) for proper weight distribution and support.

How do you add weight to tractor tires?

Adding weight to tractor tires is a process called liquid ballasting.

This is done by filling the tires with a liquid, like water or antifreeze, to make the tractor more stable and improve its grip. To do this correctly, it’s important first to determine the amount and type of liquid needed based on the size, weight, and intended use of the tire.

What is tractor tire ballast?

Tractor tire ballast is a type of weight that is added to the tires in order to improve traction and stability. Liquid ballast, usually water or anti-freeze, is used to fill the tires and provide extra support.

How do you drain fluid from a tractor tire?

To get the fluid out of a tractor tire, you need a valve core tool to unscrew and remove the cap of the valve stem, which lets the pressure out. Then use a hose or pipe to drain out the liquid ballast until it is emptied.

Can you put air in liquid-filled tractor tires?

No, air cannot be used to fill a tractor tire that has been filled with liquid ballast. Doing so could cause the tire to explode and is, therefore, unsafe. Instead, use the same type of liquid ballast that was used to originally fill the tire in order to maintain its stability and traction.

How do you put air in a liquid-filled tractor tire?

Air cannot be used to fill a tractor tire that has been filled with liquid ballast. Instead, use a hand pump to fill the tire with the same type of liquid ballast that was originally used to fill it. Before adding the liquid ballast to the tire, make sure its temperature is within the range that the manufacturer has specified.

Conclusion

In conclusion, when filling a tractor tire with liquid ballast, it is important to use the same type of liquid that was used in the original fill, and to make sure that the temperature is within the range recommended by the manufacturer.

Additionally, regular checks for leaks and valve stem damage should be made, and any damage should be replaced in order to maintain proper pressure in the tire. By following this advice, tractor tires can remain safe and stable.